Binghamton University assistant professor biomedical engineering Guy German tested the physical limits of skin in his study regarding skin mechanics.

With his research, German said he is looking to discover the physical limits of skin and the mechanical properties of it. He is also examining how skin is affected by stress and strain, and how dryness or hydration levels can affect skin structure.

Despite conventional assumptions, skin does not have a smooth, even surface. The outermost layer of our skin — the first layer of the epidermis, called the stratum corneum — has a varying surface filled with ridges, curves and bumps. Specifically, the stratum corneum is covered by a series of triangular features which are central to German’s research.

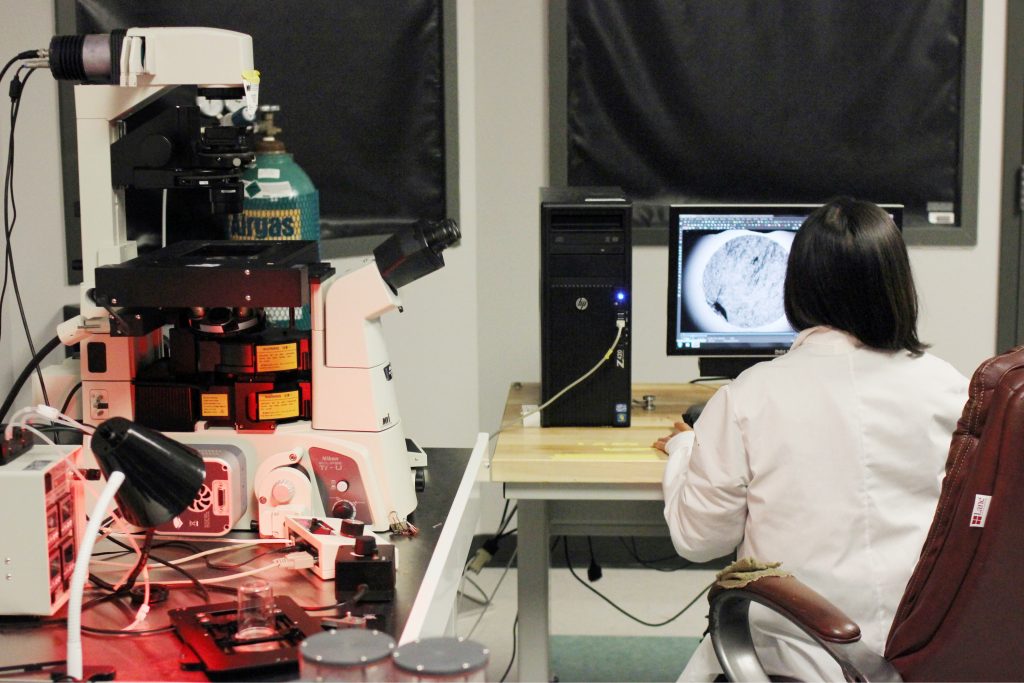

One step of the research process involves stretching skin samples, using a mechanical gripping device, and observing where cracks and tears appear and how hydration levels affect these cracks. The device used, called a uniaxial tensometer, measures the force exerted and the distance between the grips to form measurements.

“When we did observe fractures in the skin, it correlated very nicely with the regions of peak strain,” German said.

This research led to German’s team being able to predict where cracks will appear accurately, within certain parameters.

“We could measure without actually breaking the tissue; we could measure where it was going to crack first,” German explains.

Results show that cracks tended to appear along cell boundaries, instead of the full cells themselves. In most cases, skin ruptured along paths connecting cells, instead of tearing the individual cells. Tearing in this fashion technically requires more energy. In this way, these triangular features have a characteristic toughness that makes it hard to rupture the skin.

According to German, his team has been looking for ways to apply the results. While his research could have applications in the field of cosmetics, what it inspired the team to do was apply the information to materials other than skin.

German’s team also tried to look at crack propagation — the path that cracks follow — on materials such as silicon rubber. They believe that this could be applied to phone screens. Generally, when mobile phones are dropped and screens break, the cracks appear across the entire surface.

According to German, one goal would be to engineer phone screens with similar features, and fill it in with transparent material that makes it appear smooth and normal. Screens made in this way would then only crack along the edges, which would extend their usability. This research is in the early stages of development, with simple experiments being conducted on silicon rubber to create cracks at certain angles.

Xue Liu, a fourth-year Ph.D. candidate studying biomedical engineering, said that this research was significant and new.

“We did a fundamental study on how skin fails, looking at multiple levels,” Liu said. “Before us, no one proved that cracks occur [between cells] and not within cells.”