As the number of coronavirus cases in Broome County continues to increase, so do the innovative methods devised to help combat its spread.

Members of Binghamton University’s Watson School of Engineering and Applied Sciences have been contributing their engineering expertise — developing face shields, ventilator prototypes and inventive ways to sanitize personal protective equipment (PPE).

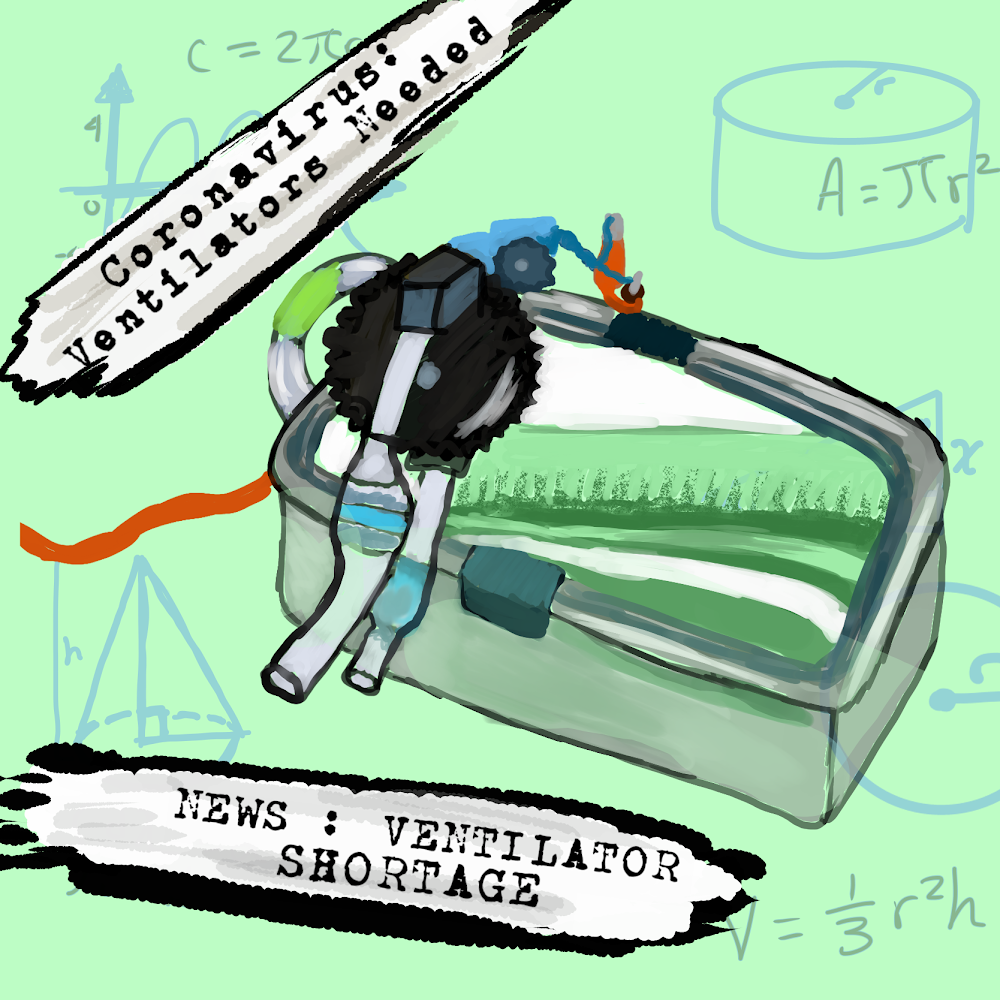

Jacob Goodman, a junior majoring in mechanical engineering, developed a ventilator prototype from his on-campus apartment using a complex valve system from items found at a local Wal-Mart.

“The ventilator prototype uses a mechanically timed valve that is assembled from four components: a 3D-printed valve housing, a 3D-printed pinion gear, a 3D-printed main gear and a servo motor,” Goodman said. “The main gear is designed with slots cut into it. The relative position and size of each slot determine the frequency and duration of each breath delivered to the patient.”

The design also consists largely of ordinary repurposed items, according to Goodman.

“The rest of the design is assembled from a lunch box, a collapsible water bottle designed for camping and vinyl tubing repurposed from a back-mounted camping water bottle,” Goodman said. “The lunch box acts as a pressure chamber, which is pressurized and depressurized by the valve. When the lunch box is pressurized, the collapsible water bottle is deflated. When the lunch box is depressurized, the collapsible water bottle is allowed to inflate with oxygen. This process repeats, periodically forcing oxygen into the patient’s lungs.”

Since the completion of the first prototype, Goodman has gained more knowledge on how ventilators operate, including settings and controls that are necessary for those used in hospital settings. Currently, Goodman is working toward refining the prototype and tweaking it for hospital use.

James Pitarresi, vice provost for student and faculty development and executive director of the Center for Learning and Teaching (CLT), who had originally challenged Goodman’s class to build a ventilator, said other students may also pursue further development within Goodman’s design.

“It is possible that some students might try to modify the design for operation in more robust environments and where the health care infrastructure is not well developed,” Pitarresi said. “However, that challenge is up to the students to accept or try a different project.”

In addition to Goodman’s ventilator design, students, faculty and staff across the Watson school have been working on developing equipment for local hospitals, which Krishnaswami Srihari, dean of the Watson school, said is a team effort.

“Several facets of the Watson school worked [to help] health care professionals in the fight against COVID-19,” Srihari said. “While our colleagues from the biomedical engineering department, led by Department Chair Kaiming Ye, worked shoulder to shoulder with colleagues in [the Watson school’s Fabrication Lab], led by Vincent Brady [manager of engineering laboratories and learning environments], another team worked on 3D printing of ventilator adaptors — this team included [Assistant] Professors Jia Deng, Fuda Ning and their graduate students. Professor Mohammad Khasawneh helped coordinate these [projects]. [Assistant] Professor Scott Schiffres and his grad students worked on the assessment of different materials that could be used as filters in 3D-printed N95 masks.”

As of late March, the development of full-face shields involved a three-step modification of face shields provided by Lourdes Hospital, according to an interview with Vincent Brady in a B-Line news addition.

Since then, the design has made steps towards scaled production, according to Srihari.

“We, Watson [Fabrication] Lab, also developed ‘full-face shields,’” Srihari said. “We developed two different designs — one with a 3D-printed headband and the other with a different design. We then identified two companies that can produce these face shields at scale and provided their information to hospitals and to SUNY for dissemination to other venues or campuses.”

Significant progress has also been made in producing PPE sanitation devices, which are already being used locally, according to Brady.

“We have built and delivered two systems — one to [United Health Services] and one to Lourdes [Hospital],” Brady said.

As members of the Watson school continue to design and develop new ways to help combat the COVID-19 pandemic, Srihari praised their work.

“Our graduate students, faculty and staff have displayed excellent teamwork in these endeavors,” Srihari said. “Our colleagues in [the Watson school] are an excellent team, and we are certain that we, our campus and the Watson school, will emerge much stronger from these surreal times.”